English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

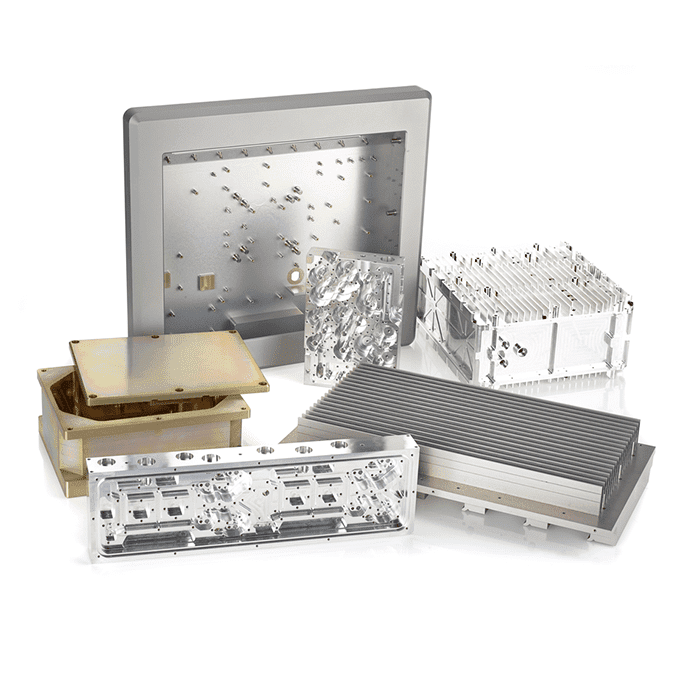

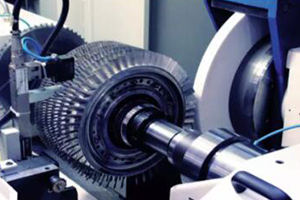

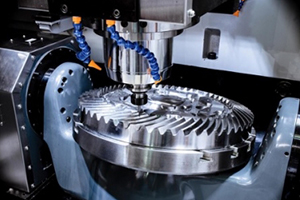

Medical equipment parts processing

Medical equipment parts processing Semiconductor Precision machining mfg

Semiconductor Precision machining mfg Agricultural machinery parts processing

Agricultural machinery parts processing

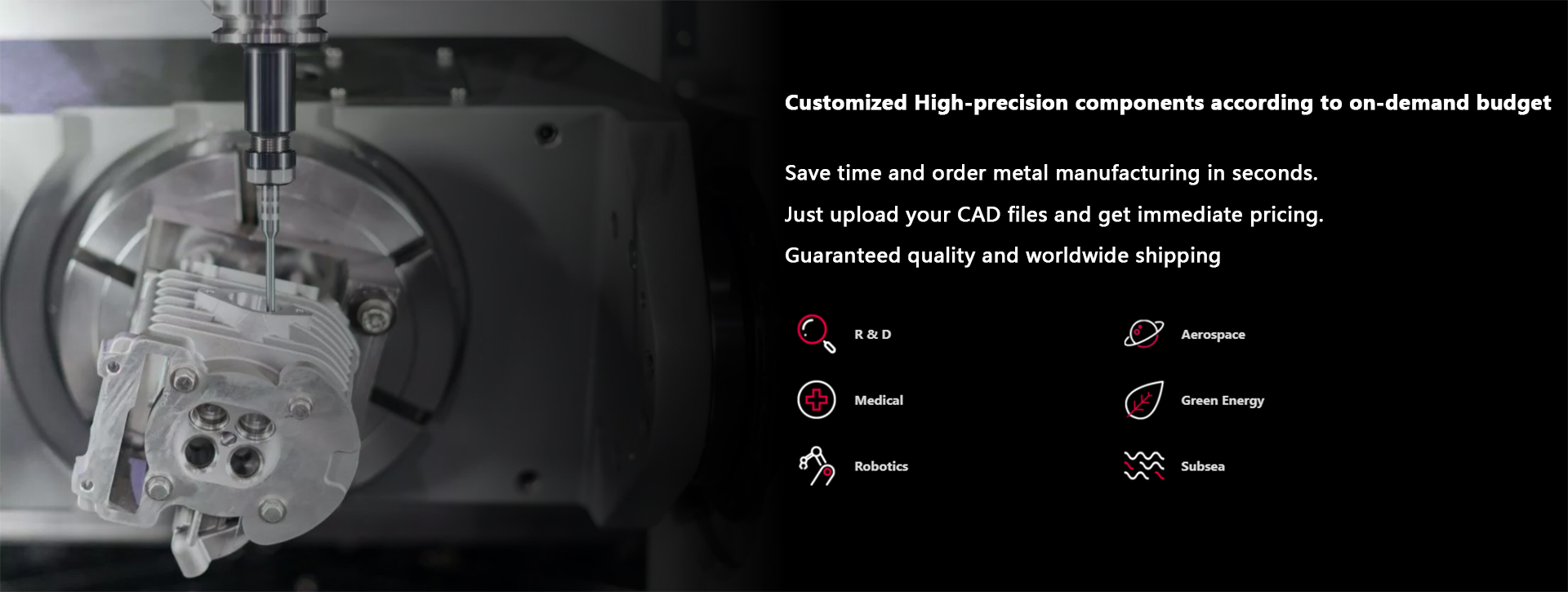

About Dongguan HX Technology CO., LTD

HXTech are specialized in manufacturing

custom precision Machining parts,

Casting Parts, Hardware, Meal/Plastic Mold Design & Build and also Production.

We offer extreme flexibility for your project needs without MOQ limited.

HXTech machining will provide you with the following benefits and advantages:

·More saving nice manufacturing cost.

·State-of-the-art manufacturing facilities.

·On site manufacturing supervision for quality control.

·Bilingual engineers reporting on your project 7days/24H.

·Reasonable short lead time.

1.Quality Assurance:

a.problems can be refunded,we are the only supplier in China support 7 days refund money.

b.In case of bad quality for sure we accept to refund money.

c.To ensure maximum performance and quality, all of HXTech's machined parts&molds parts are one by one fully inspected.

2.Delivery guarantee:

(compensation for delays)

Time is gold for your and for us,

we have professional team work whom can making nice quality within short time,

if we delay delivery time one week we offer you 3% total amount,

2weeks we offer you 5% of amount,Support Door to Door transportation.

3.After-sales guarantee:

You have to know that “many Chinese companies offering you very cheap price to attract your attention,

but after placing the orders nobody care about after sales service.

but we are not the same as we have special team work for A.S.S and you will find us any time,

also we will keep in touch with you for all your orders details. As we would like to have long term business not “one time business.”

4.Win-win culture:

We know that many suppliers break down the quality to meet the low price requirement,

but we never do that, because it is not our company culture ,

but we trust if you can tell us your target price,

we will do our best to meet your price In the last few years we know

that many Chinese supplier break down quality fo make more profits, but with us it is totally different,

as we trust the business must be “WIN-WIN situations.”

5.Well knew reputation:

If you check the black list for China Export suppliers you will not find

our company name as we never cheat our customers.

6.Legal Liability:

You know why many customers allover the world like to do business with us,

because we are the only supplier can offer:

*Confidentiality agreement

*full refund agreement

*delivery time agreement

*international business legal contract.

7.Socially responsible:

*As star company, all our products has been passed environmental protection.

*All our items are environmentally friendly.

*all our products have a very nice feature, it is energy saving.

*all our products support (environmentally friendly and energy saving)

INDUSTRIES

Aerospace & Defense

Automotive

Semiconductor

Optical Communication

Electronics

Energy

Medical Equipment

Automation

Robotics

Customized Parts

DepartmentBossard (Switzerland)

One of strategic source to achieve our

quality and quick turn around parts needs

Quality Engineering.

BD Biosciences

We are very satisfied about the result.

and experience working with

HXTech.

Corporate Purchasing

COESIA Group

From simple parts vendor to our list of

superior suppliers to serve a number

subsidiers of our group.

Design Engineer Director

ITW Dynatec

Thanks HXTech Fellows, for your rapid

response in reverse engineering.

prototype and low-volume production

more new projects send to your way!

Fasteners Buyer.

Foxconn

Well donel Thanks for the long-term

efforts in the high strength bolt

experiment, the related product has been

put into mass production smoothly

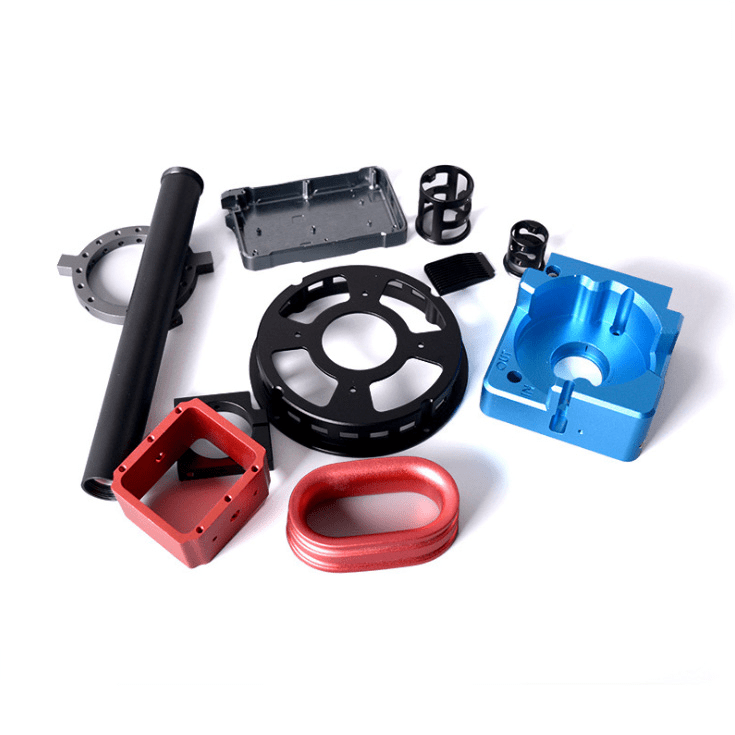

Hot Products

Customized machining of front and rear wheels of motorcycles

Customized machining of front and rear wheels of motorcyclesThis product is used in the design of high-speed motorcycle racing wheels. Customized machining of front and rear wheels of motorcycles needs a higher speed than ordinary wheels. Therefore, the produc......

Fixture accessories

Fixture accessoriesWe Fixture accessories differently from other services and ask questions before starting manufacturing to help our customers make better and more cost-effective Fixture accessories.

Motorcycle Car Charger Round Charger Fast Charge PD Charger Modification Accessories Double Fast Charge Waterproof

Motorcycle Car Charger Round Charger Fast Charge PD Charger Modification Accessories Double Fast Charge WaterproofHXTech is equipped with more than 50 advanced CNC processing equipment at home and abroad, such as has slow-moving wire cutting machines, optical grinding, CNC lathes, and CNC machining centers from J......

Coulter components

Coulter componentsThis coulter is not only durable but also versatile as Coulter components mounts on most implements and toolbars.

Latest News

Global Micromotors spare Market Record 2021

The international market for Micro Motors is expected to plunge by -17.9% in the year 2020 before recouping to reach US$ 35.6 billion by the year 2027, tracking a post-COVID-19 CAGR of 4.1%, over the analysis period 2020 with 2027.

24 kinds of commonly used metal materials for machining and their characteristics!

Do you know the 24 commonly used materials for machinery and mold processing?

Get CNC wire cutting processing in four steps

nalyze and review the processing pattern. According to the existing processing equipment, considering the feasibility of this process method, processing cannot be achieved in the following situations: a workpiece with a narrow slit smaller than the diameter of the electrode wire plus the discharge g...

How to make a machining accuracy control plan

We will sort out and classify the solutions to the problem of geometrical size tolerances in machining in four aspects: workpieces, tools, fixtures, and machine tools, and put forward some suggestions. In mechanical processing, the unity composed of machine tools, fixtures, tools and workpieces is ...

Inquiry For Pricelist

2D/3D drawings, material

Quality inspection requirements (testing equipment)

Testing requirements

payment terms

Shipment date

Monthly annual usage estimated usage

Whether it is an urgent item (lead time xxx days)

Requirements for suppliers (certification, scale...)