English

English Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Sundanese

Sundanese  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик

Products

- Medical equipment parts processing

- Semiconductor Precision machining mfg

- Agricultural machinery parts processing

- Medical equipment accessories

- Mining and Petroleum Machinery Parts

- Construction equipment precision machinery parts

- Automated machinery precision parts processing

- Aerospace precision parts accessories

- Precision machining of auto parts

- Customized mechanical pulley

- Mould

- Precision machining of electronic products

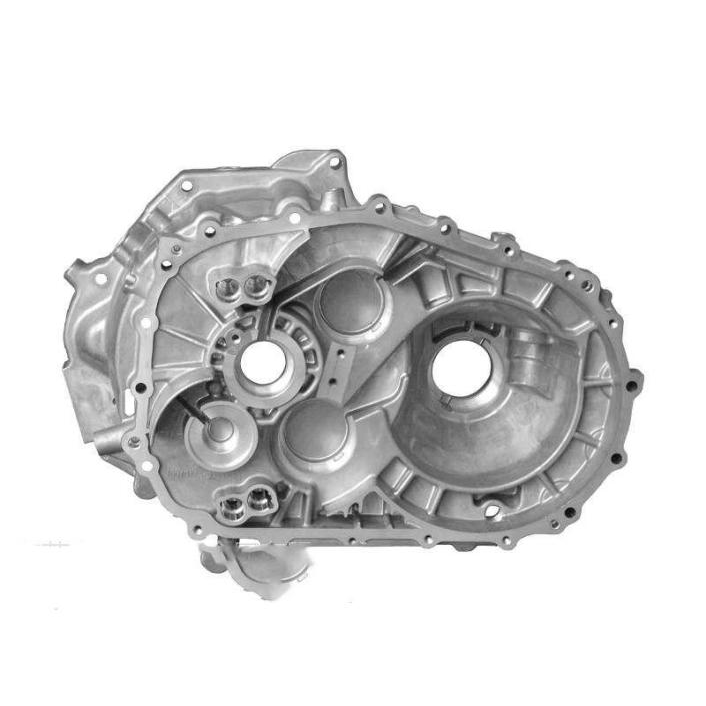

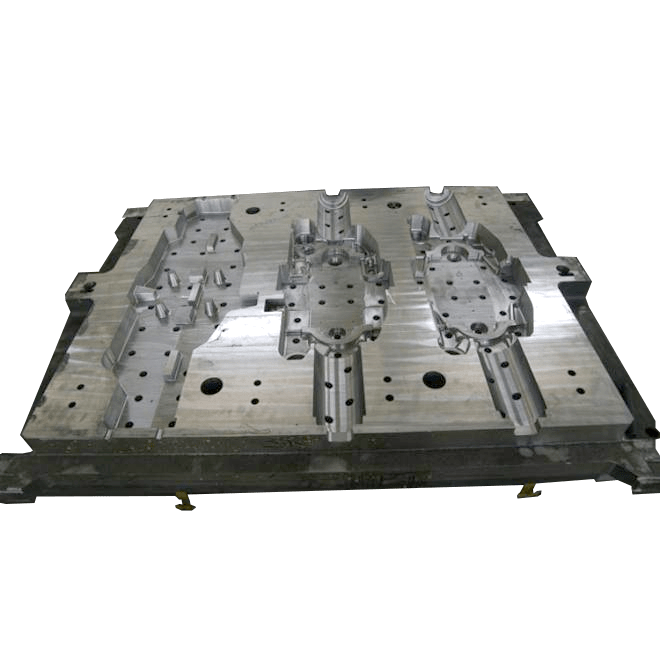

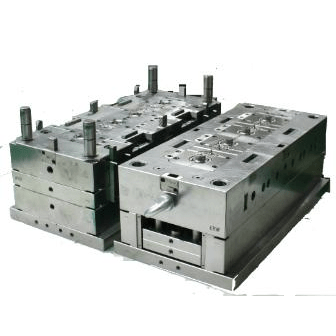

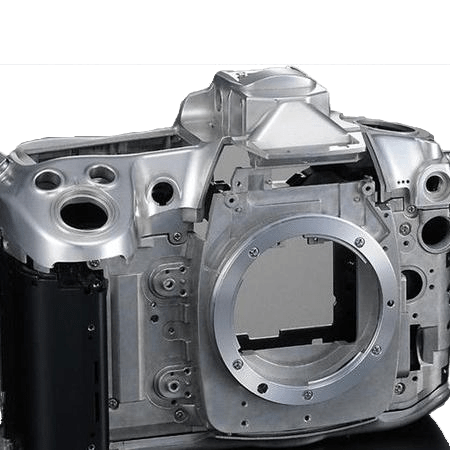

Aluminum casting mold

As a custom manufacturer of Aluminum casting mold, HXTECH can manufacture custom manufacturers of aluminum molds used in construction, aerospace, automotive, construction, electrical, furniture, food, lightning, marine, medical and military industries. Our Aluminum casting mold are manufactured according to your specifications, meet your budget and warranty requirements, and use European or Chinese grade steel.

Send Inquiry

Product Description

Die Casting Mould——Aluminum Casting Mould

As a custom manufacturer of Aluminum casting mold, HXTECH can manufacture custom manufacturers of aluminum molds used in construction, aerospace, automotive, construction, electrical, furniture, food, lightning, marine, medical and military industries.

Our Aluminum casting mold are manufactured according to your specifications, meet your budget and warranty requirements, and use European or Chinese grade steel.

Product Details:

Product Name: Aluminum Casting Mould

Type: air solidified castings, green sand castings

Material: aluminum alloy, steel alloy, graphite, tool steel, stainless steel and copper alloy

Functions: Prototyping, molding, manufacturing, vertical CNC machining, robotic polishing and vibration finishing, multi-spindle drilling, heat treatment, electrofusion and polishing

Application equipment: diesel engines, agricultural machinery, lighting, international internal combustion engines, machine tools, manifolds, pistons and pumps and pumping equipment

Application areas: automotive, construction, textile, agriculture, electric power, power generation, transportation, industry, small/large electrical appliances and food industry

Application: suitable for brackets, suspension components, valve covers and other various applications

Tooling products: assembly fixtures, machining fixtures, test fixtures, composite laminated tooling, injection mold tooling, vacuum forming tooling and special application tooling

Services: design, prototyping, reverse engineering, CAD modeling, CNC milling, CNC turning, grinding, TIG welding, assembly, bonding, EDM machining, polishing, heat treatment, surface treatment and texturing, gravity die casting, low pressure, blow molding , Glass fiber and concrete molds

Size: Maximum 64 inches (length) x 48 inches (width) x 40 inches (height).

After sales service

WE support 24Hours/7D afer sales service online.

High levels of Customer Service and Customer Satisfaction are our TOP priorities.

We promise we can make you happy if you give us a fair chance.

If you are happy with the product, we would really appreciate if you left a positive feedback.

If you have any issues or are unhappy with the item for any reason.

Please do not hesitate to contact us first before leaving any negative feedback.

We will do our most to resolve this situation.

FAQ

Q1、Are you a manufacturer? Do you have a factory?

A1:We are a professional manufacturer for more than 15 years and we have factories. You can follow our google map address.

Q2、Can I get samples for free? Is it possible to ship for free?

A2:In view of account the uniqueness and confidentiality of customized non-standard Mould, after confirming all the detailed information, it is necessary to charge you for samples and you need to bear the corresponding shipping costs. If you subsequently purchase a large number of products, we will follow your order as much as possible with some discounts and exemption of sample fees.

Q3、Do you able to make OEM?

A3:Yes, it is. We have laser machines that can mark your logo and size. We can also design stickers with your logo.

Q4、How about your delivery time?

A4:Depending on the size and quantity and complexity of the process, the delivery time is usually within 5-15 days. When we know the detailed product acceptance criteria and technical requirements details, we can tell you the exact delivery time.

The following technical requirements shall be provided before purchasing project details:

Part information (2D/3D drawings, material, critical dimension tolerance, weight, purpose, etc.)

Special materials (purchase channels, designated suppliers)

Designated process (subdivision process is best)

What equipment is needed?

Monthly/annual usage/estimated usage

Project intent/purpose

Project development cycle

Requirements for suppliers (certification, scale)

Whether it is an urgent item (lead time xxxx days)

Focus on the points of concern (price/quality)

Difficulties of the product

Complicated problems with existing products

Are there requirements for the product life cycle?

Quality inspection requirements (testing equipment)

Testing requirements

Target price

payment terms

Shipment date

Brass Casting Mold

Brass Casting Mold Aluminum casting mold

Aluminum casting mold Invest casting mold

Invest casting mold Alloy Die Casting Mould

Alloy Die Casting Mould Zinc Die Casting Mould

Zinc Die Casting Mould Magnesium Die Casting Mold

Magnesium Die Casting Mold